3D Printing Most common problems for beginners Ram Peripherals 3D Printing & Disc

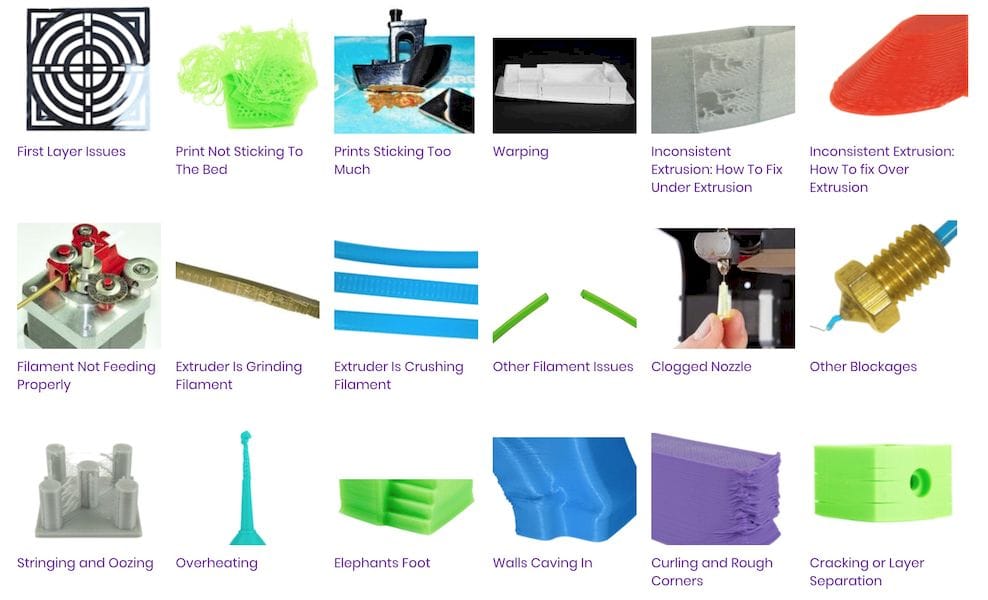

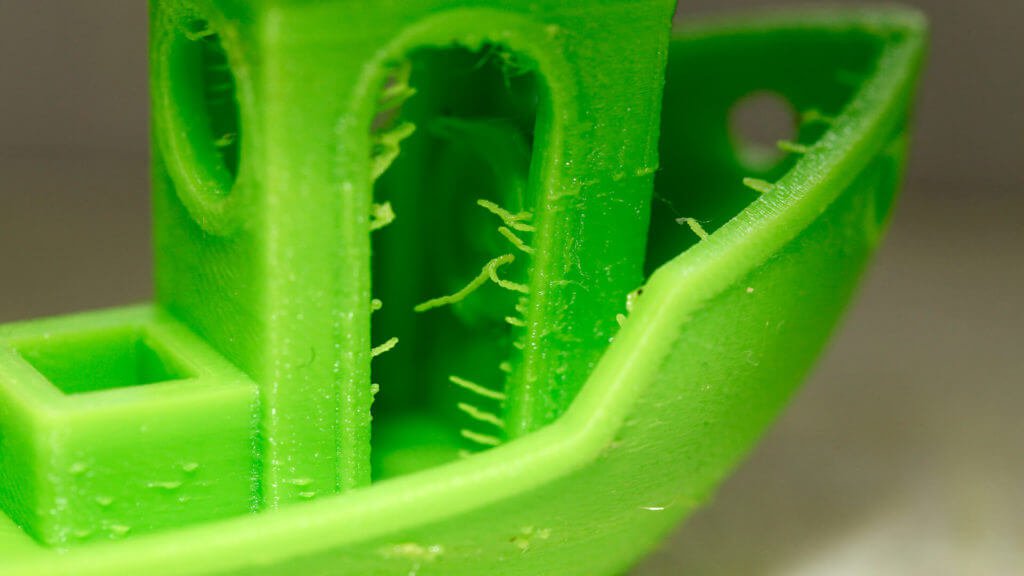

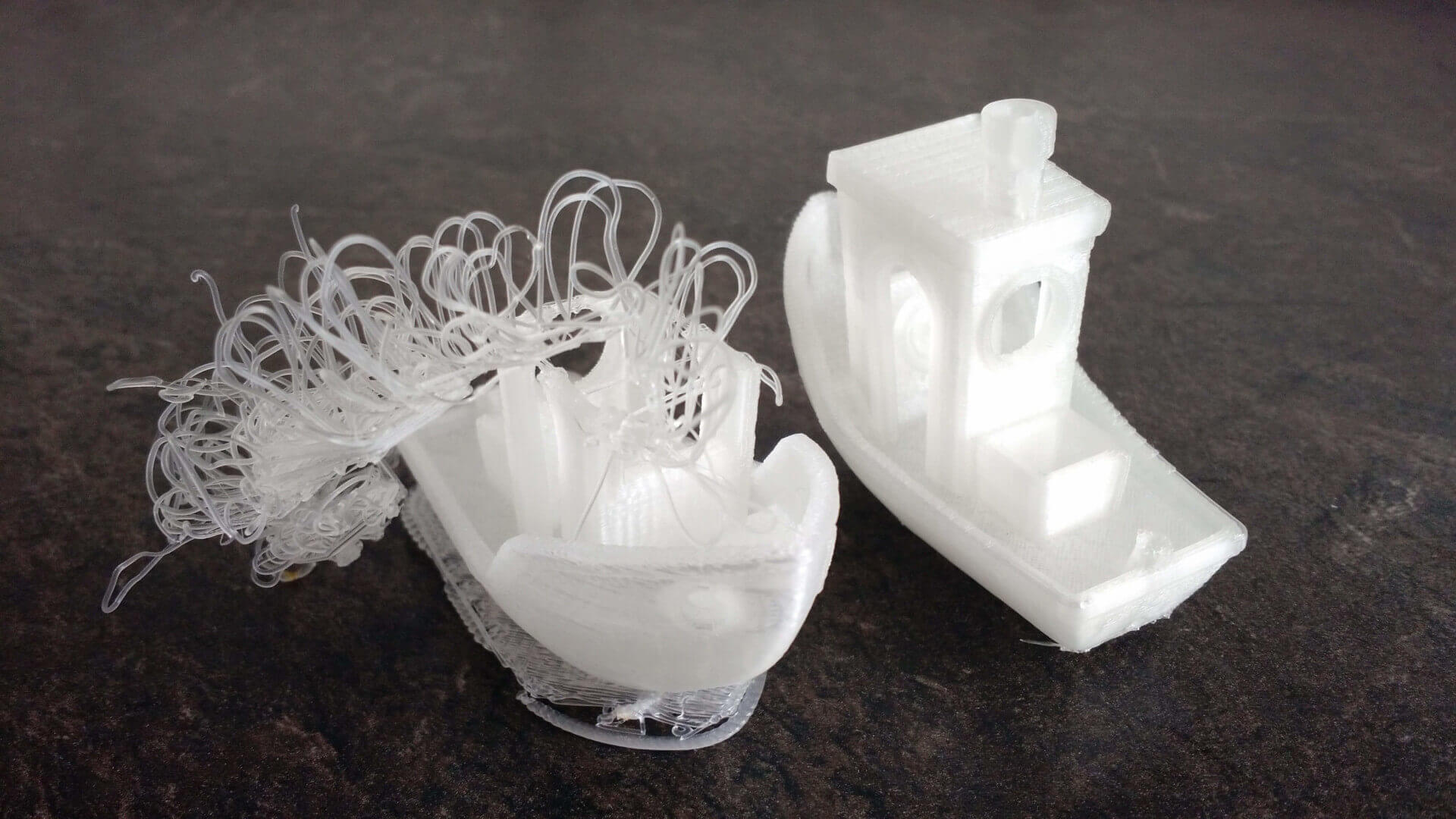

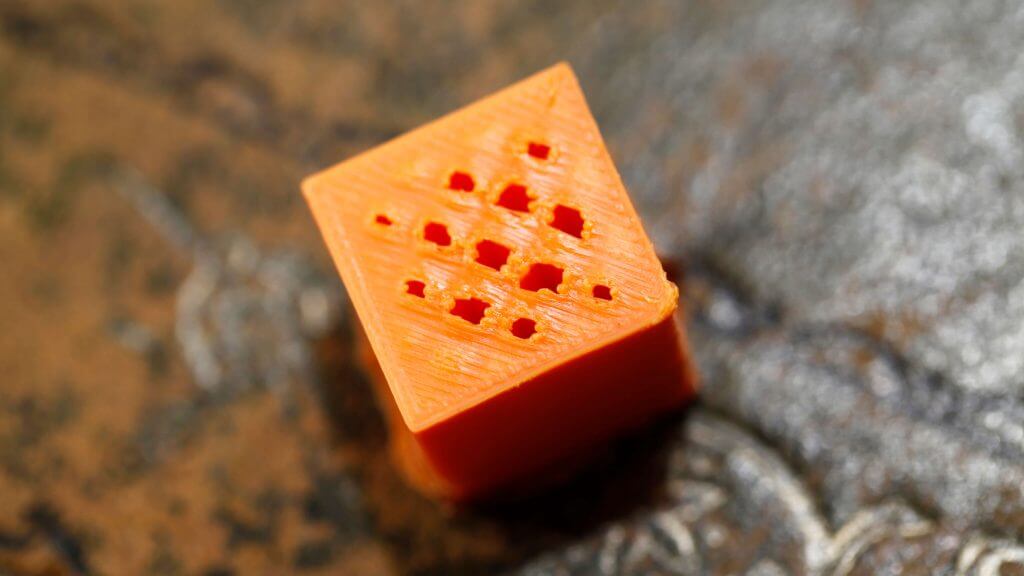

October 26, 2023 3DSourced Rigid Ink, 3D Printing Guides, Guides Key Takeaways 3D printing problems: The article explains common 3D printing problems, such as poor adhesion, warping, clogging, stringing, and over-extrusion.

Troubleshooting Guide to 7 Common 3D Printing Problems, our solution. Geeetech

The great news is you can fix some of the most common 3D print problems yourself. Follow Gambody's 3D printing troubleshooting guide that reflects solutions to 10 problems hobbyists face most often. 1. No Filament Coming Out of Extruder Some FDM printers display the filament reel, and you can see when you are out of filament.

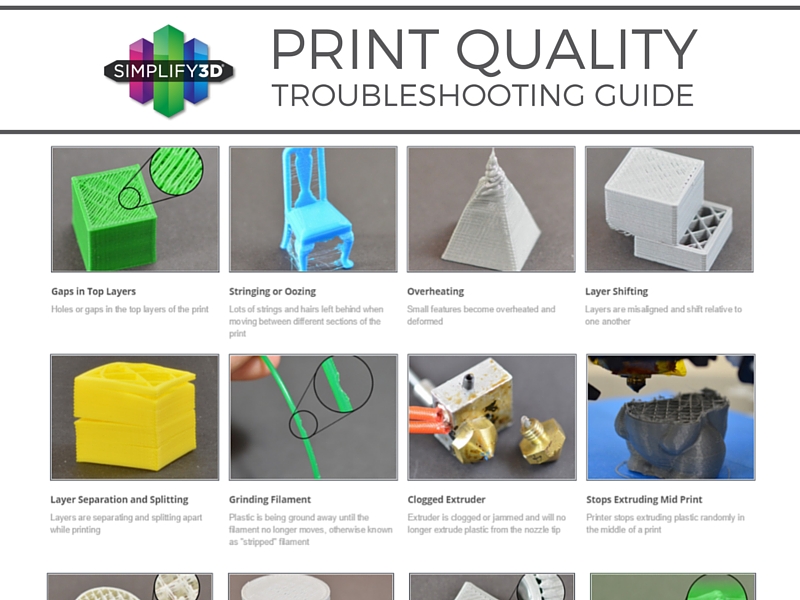

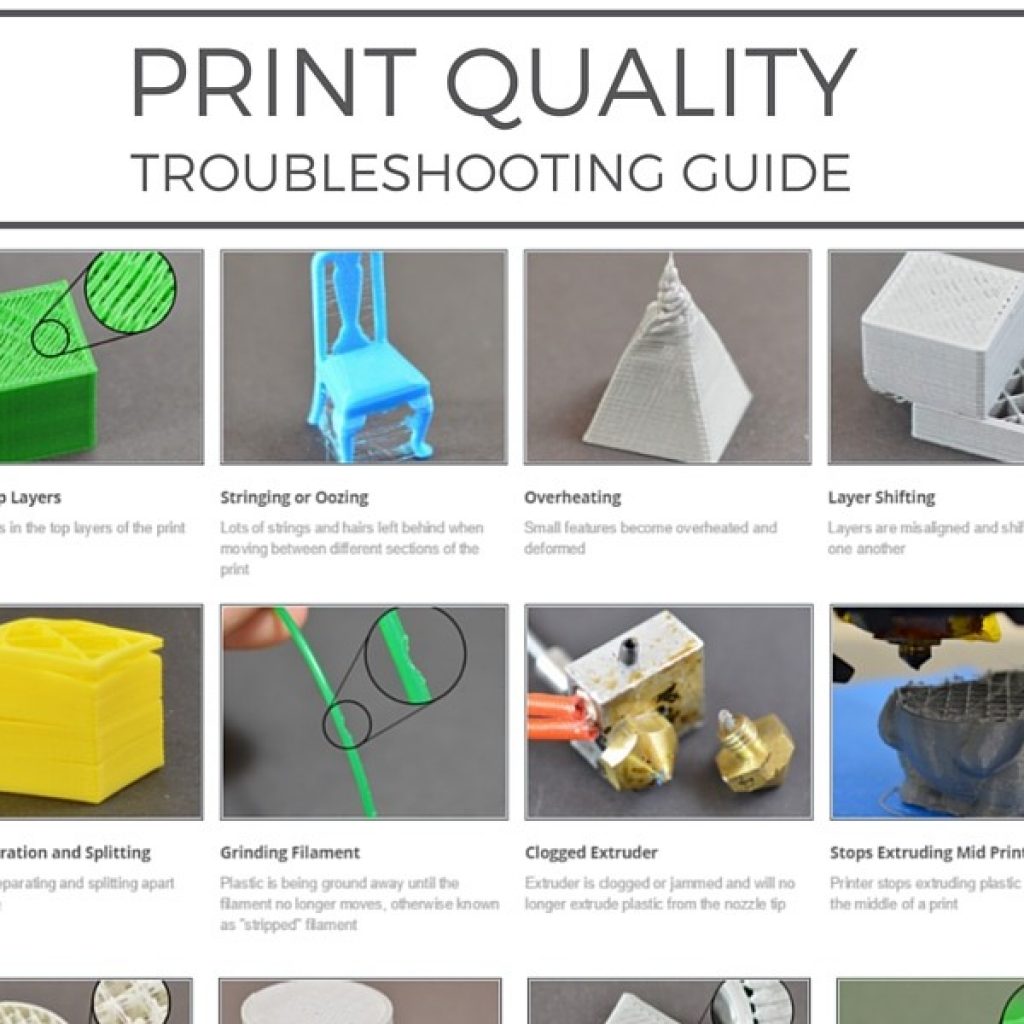

Simplify3D Introduces 3D Print Quality Troubleshooting Guide

Causes for clogging. Unclog the nozzle with acupuncture needles. Hot and cold pulling. Teflon switching. Adjusting the printing parameters. If you don't know how to fix it, dissasemble the extruder and hotend. 👋 That's it for the 3D printing troubleshooting guide by Bitfab.

Guía de resolución de problemas de impresión 3D 3D Neworld

First layer issues This is by far the most common 3D printing problem, and probably the first one you may encounter. The first layer is the essential one because it is the base. Troubleshooting > Print Quality Troubleshooting Plus 1.75 mm MK2.5 MK2.5S MK3 MK3S MINI MK3S+ MINI+ MK3.9 88 The Benchy hull line

Six Good 3D Printing Troubleshooting Guides « Fabbaloo

Key Takeaways Warping and curling in 3D prints can be prevented by adjusting the bed temperature, leveling, and using materials with lower shrinkage rates. Layer shifting is caused by loose or faulty printer parts; regular maintenance of mechanical components can prevent this issue from occurring.

New Guide Makes It Easy for Anyone to Improve Their 3D Print Quality Simplify3D Software

Almost every 3D printer has a fixed nozzle size. This size determines the resolution. In most cases, a nozzle diameter of 0.4 millimeters is used. You may experience problems if you print very thin areas that are smaller than the size of the nozzle. The thinner the printed areas should be, the smaller you should choose the nozzle diameter.

Simplify3D Releases Comprehensive Troubleshooting Guide for All Your 3D Printing Issues

Having problems with your 3D printer? Don't worry - 3D printers sometimes fail, but most issues are easy to fix with basic tools and a little patience. Today we'll cover the 9 most common problems you're likely to face while 3D printing, and teach you how to fix them in a few easy steps.

Simplify3D Releases Comprehensive Troubleshooting Guide for All Your 3D Printing Issues

You can correctly set the Z offset of your 3D printer manually by adjusting the nozzle height as you place a piece of paper on the bed. You can find the Z offset setting on the menu of your 3D.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

Jams? Clogs? Leveling? ERRORS!?The hobby of 3D printing can get frustrating fast! In this video I'll be covering 10+ common problems I've been seeing across.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

The 12 most common problems in 3D printing and how to fix them Here is the solution to your 3D printing problems By: Viola When I have started with 3D printing I expected those perfect prints seen on Instagram slipping off from the plate so smoothly as they would be buttered. I can tell you it didn't turn out so well at first.

5 Common Problems Faced with Metal 3D printing And How You Can Fix Them FacFox Docs

Updated Sep 6, 2022 Complete 3D printing troubleshooting guide. All common 3D printing problems and their solutions. Includes both FDM and SLA 3D printing issues.

Troubleshooting Guide to 7 Common 3D Printing Problems, our solution. Geeetech

1. Warping 2. Elephant Foot 3. More First Layer Problems 4. Layer Misalignment 5. Missing Layers 6. Cracks in Tall Objects 7. Pillowing 8. Stringing 9. Under-Extrusion 10. Over-Extrusion 11. Shifting Layers 12. Blocked Bowden Nozzle

How to Solve Most Common 3D Printing Issues1 Extrusion Problems

How To 3D Printer Troubleshooting Guide Use this guide to help you identify and solve the most common issues that may occur while 3D printing. Updated on August 24, 2023 by MatterHackers When printing, unexpected challenges may arise that will need to be resolved in order to complete a successful print.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

The most basic 3D printer troubleshooting is to level the print bed. The print bed is typically manually leveled, or if lucky, your printer may have an auto bed leveling feature.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

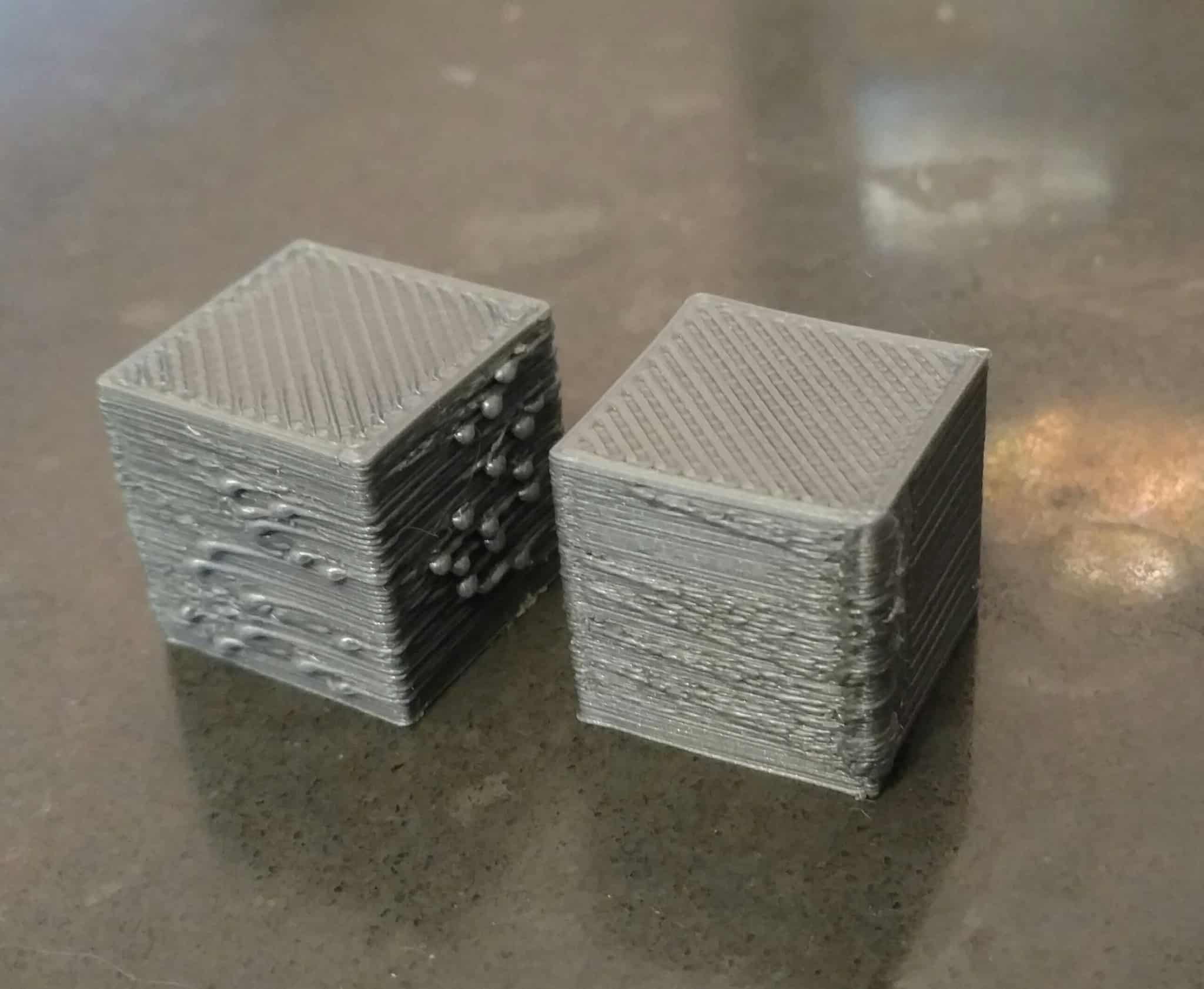

4 How to Solve the Most Common 3D Printing Problems What do you do when you are trying to run a 3D print and it just doesn't come out right? Undoubtedly, you'll have faced a situation where your prints come out skewed, with a rough surface finish, with blobs or with plenty of stringing.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

Level the bed and increase first layer height and width. Poor adhesion: Caused by low bed temperature, dirty bed, or incorrect adhesive. Clean the bed, raise the temperature, and use suitable adhesive. Inconsistent first layer: Caused by different filament types or printer models.